My helper was present today. Once she has built it she can ride it.

My helper was present today. Once she has built it she can ride it.

In the end I realised that the crankshaft taper on the CG250 crankshaft is different to the crankshaft taper on the old 6v flywheel crankshaft. The CG250 CDI engine appears to have a longer crankshaft on the flywheel side. I don’t want to machine the crankshaft on the CG250 engine, so that’s it, I’ve given up and re-assembled to CG250 engine to use as is.

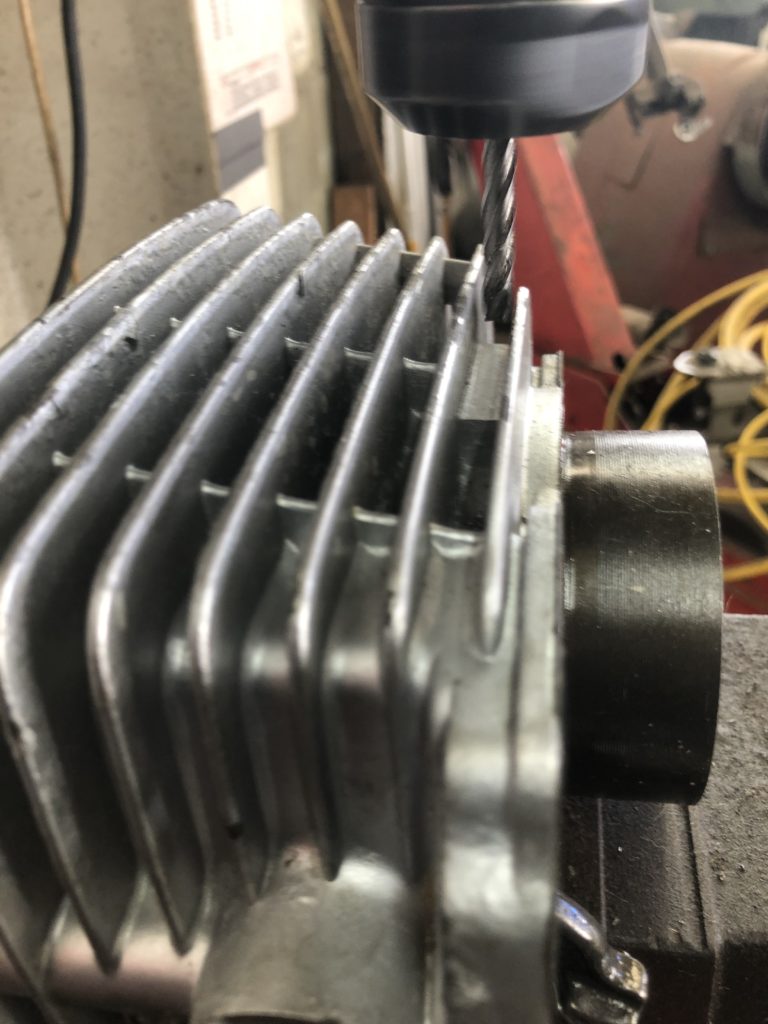

I bought a 167FMM CG250 (233cc) Chinese copy engine. I’d like to use it in my recently completed silver CG125 but as the old CG125 is 6v with points ignition and the CG250 is 12v with electronic ignition I don’t much fancy changing the wiring harness and all the light bulbs. So I have been investigating swapping the crankshaft and cylinder, piston etc to some spare CG125 crankcases I have. The first issue is the crankcase cylinder opening size isn’t big enough to accept the larger cylinder liner, so today I set about boring the crankcases to accept the bigger liner.

I bought a 167FMM CG250 (233cc) Chinese copy engine. I’d like to use it in my recently completed silver CG125 but as the old CG125 is 6v with points ignition and the CG250 is 12v with electronic ignition I don’t much fancy changing the wiring harness and all the light bulbs. So I have been investigating swapping the crankshaft and cylinder, piston etc to some spare CG125 crankcases I have. The first issue is the crankcase cylinder opening size isn’t big enough to accept the larger cylinder liner, so today I set about boring the crankcases to accept the bigger liner.