And just like that, after 15 good years at Honda my time to start a new chapter has begun. I’m excited about the future ?

New to me car

New Motorcycle Lift

1977 Silver CG125 sold

CG110 Points setting

1973 Honda CB350 start up and walk around

Re-assembled with correct engine

I put this lovely old think back together over the last couple of days. Fortunately I had all the bits that were missing in my parts hoard including a freshly rebuilt engine. Runs great. Really needs a complete strip down and frame paint and new wheels, mudguards and muffler but I can’t be arsed to do another one so I’ve offered it for sale as is.

That’s it, I’ve had enough

Front wheel lacing

Cordless Tool Stand

Garage improvements

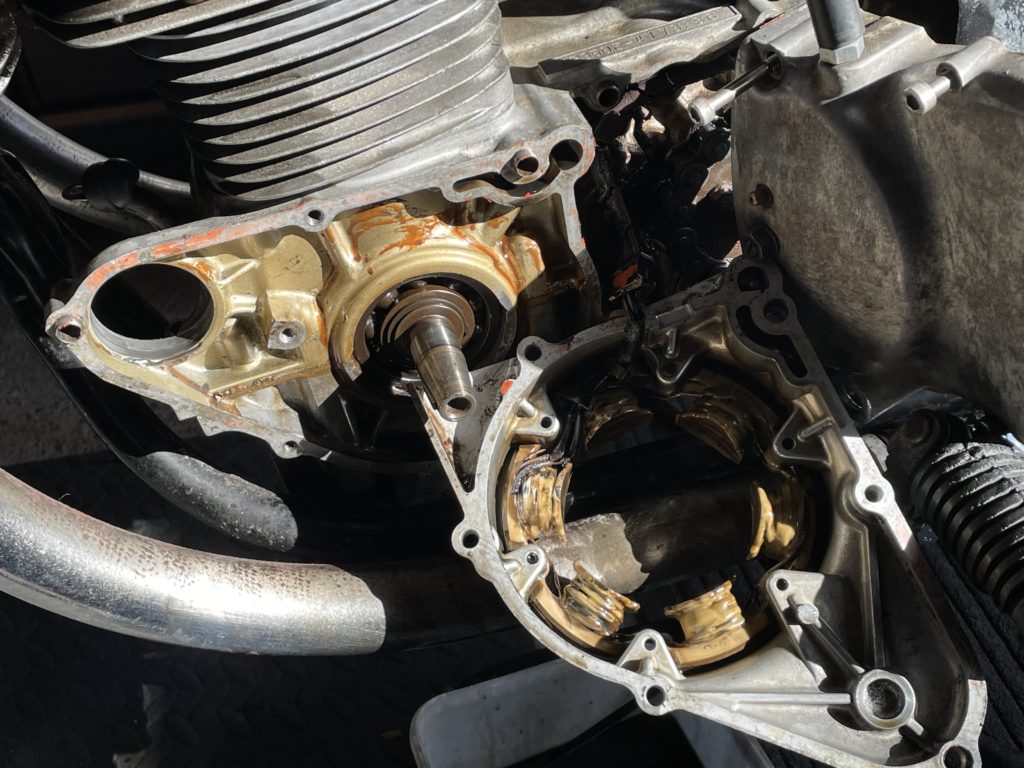

Electric Starter Fixed

I bought a rebuild kit for the starter motor. Glad I did. The end cap bush was oval. I found the reason it stopped working. Someone had over tightened the terminal post and torn the main internal connector off at it rotated. Replaced bothe bushes, brushes, lubed bearing and soldered the internal conductor back to the terminal post. Took we 4 attempts to reassemble, adjusting end float, until it spun freely with a bench test. Re-installed it and the bike fired right up, instantly ?